The production of quality solar panels is a complex process involving many steps and components. In this guide, we will walk you through the basics of solar panel manufacturing.

Solar power is a crucial component of a future based on sustainable energy. As the demand for clean energy sources continues to increase, so too does the need to understand the production system of solar panels.

In this guide, we will cover the basics of solar panel manufacturing — including the various components of a solar module, the photovoltaics manufacturing process, the necessary steps for assembling a solar production line, the cost of production, and the potential benefits of automation.

Introduction to Solar Panel Manufacturing

Manufacturers have refined the process of making solar panels over the years to make solar energy more accessible and affordable. Solar panels are made up of photovoltaic (PV) cells, which convert sunlight into electricity.

To ensure the optimal performance of solar panels, it is crucial that every component is meticulously manufactured and assembled. In this guide, we will provide a comprehensive overview of the entire process — starting with the various components of a solar panel and culminating in the automation of the production line.

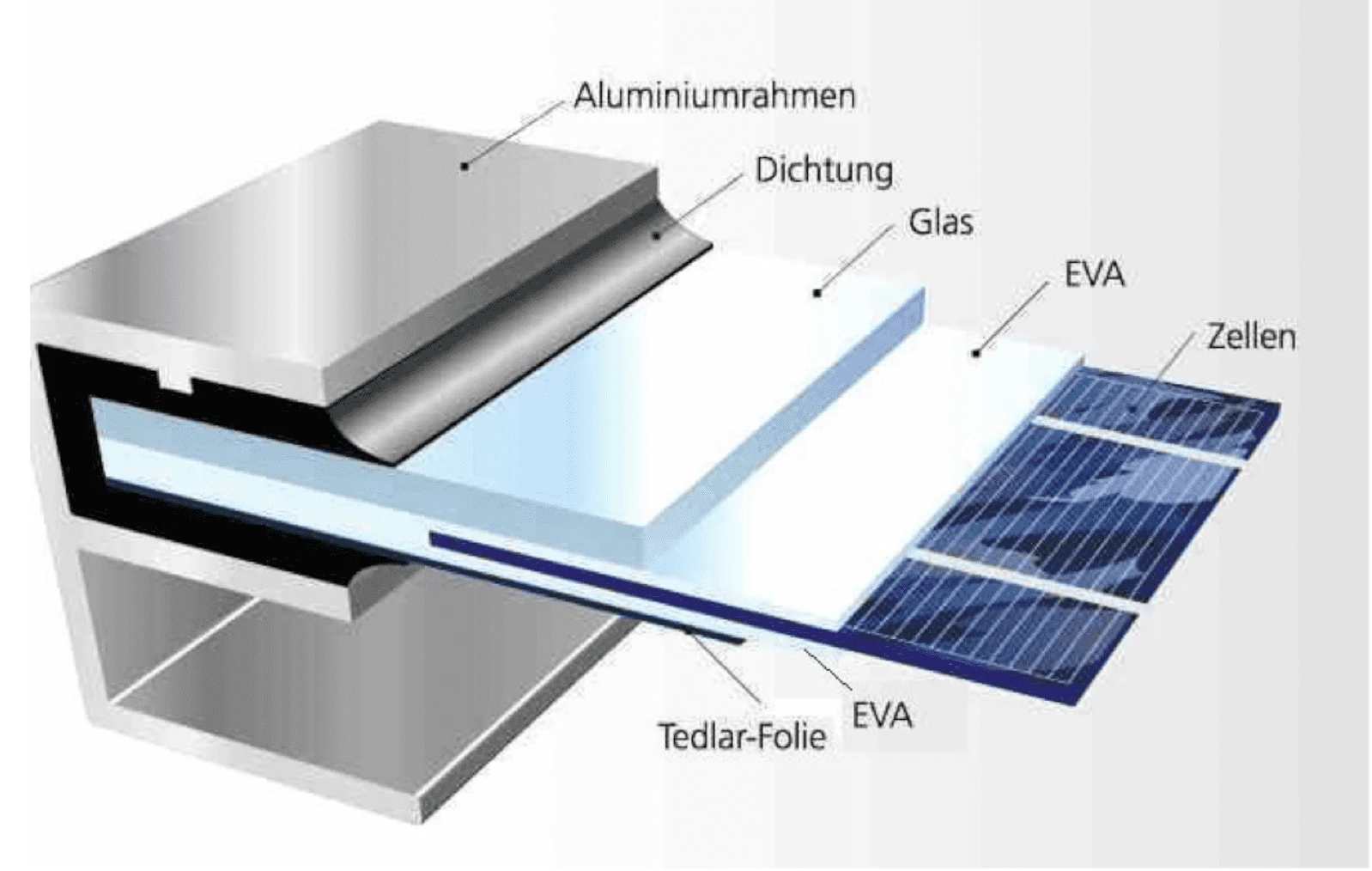

Overview of the Parts of a Solar Panel

The parts of a solar panel are essential to understanding the production process. Each panel cell is made up of a variety of components, including:

1. The PV cells

2. A backsheet

3. A glass cover

4. A junction box

5. A frame

6. A glass cover

The PV cells are the most important part, since they are responsible for converting sunlight into energy and then into electricity. The glass covering protects the cells from the elements, while the framing helps to stabilize the panel. Lastly, wiring is necessary to connect the panel to an inverter and the rest of the solar system.

Photovoltaic Manufacturing Process

The photovoltaic (PV) manufacturing process is the first step in the production of solar panels. This process involves the fabrication of PV cells, which are made up of semiconductor materials such as silicon.

The operator cuts the cells into small squares and places them on a substrate. The substrate is then treated with a special chemical to create an electrical field between the cells. This process is referred to as “doping” and is necessary for the cells to convert sunlight into electricity.

Step-by-Step Guide to Assembling a Solar Production Line

Once the cells have been manufactured, they must be assembled into a solar panel. This process involves several steps, including attaching the cells to the substrate, adding the glass cover and frame, wiring, and testing.

The first step is to attach the cells to the substrate, usually with solder. The next step is to add the glass cover and frame, which helps protect the cells from the elements. The wiring is then connected to the cells in order to transfer the electricity to the inverter.

Finally, the panel is tested to ensure that it is producing the desired amount of electricity.

Choosing the Right Equipment for Solar Panel Module

The basics of solar panel manufacturing are very important when it comes to the solar panel production business. Selecting the appropriate equipment is crucial to ensure top-notch outcomes. In particular, a production line requires various types of tools and machines, including soldering tools, wire strippers, drills, and testing equipment.

It is important to select the right equipment for the job, since this will help ensure the efficiency and safety of the production process. Additionally, high-quality equipment will reduce the cost of production. In order to choose the right equipment, you need strong knowledge of the basics of the solar panel manufacturing process.

Determining the Cost of Solar Panel Production

The costs of solar panel manufacturing depend on several factors, including the type of solar panel, the size of the panel, and the quality of its components.

The cost of the components, such as the PV cells and other materials, will vary depending on the manufacturer. Additionally, the cost of the equipment and labor must also be taken into consideration. The cost of solar panel production will also depend on the scale of the project and the desired output.

Automating the Solar Module Production Process

Automating the solar production process can reduce costs and improve efficiency by decreasing the amount of labor needed, as well as the time needed to complete production.

Automation can also increase the accuracy of the production process, which will decrease waste and improve the quality of the final product. Automation can also reduce the cost of solar panel production by decreasing the amount of resources needed to complete the process.

Troubleshooting Issues in Solar Production

There are several common issues that can arise during the production of solar panels, including electrical problems, defective parts, and improper wiring. Faulty connections or components can cause electrical problems, while defective parts may lead to less efficiency.

Improper wiring can also lead to decreased efficiency and cause the module to overheat. In order to prevent these issues, it is important to use high-quality components and ensure that all connections are secure. Additionally, it is important to properly test the panels before installing them.

Conclusion

The production of solar panels is a complex process that involves many steps and components. This guide serves as a general overview of the process of manufacturing solar panels.

In future guides, we will cover in detail the various aspects of solar panel production, including the parts of a solar panel, photovoltaic manufacturing, assembling a solar production line, the cost of production, and the benefits of automation.

Additionally, we will also go into greater depth about choosing the right equipment for solar panel production and troubleshooting common issues in solar panel production.

Please sent me our contact

Hi, thanks for showing interest in our services. Please send us a message here: https://www.pvknowhow.com/contact/

Please help me invest in solar power panels production

Hello actually I want to start my startup of solar plant manufacturing buisness in india can you guide me about how to start from zero

Good luck