In this article, we look at how the frame is placed on a solar module using a framing machine. We look at how renewable energy panels are packed and sorted before they are shipped to customers.

Overview Of Solar Panel Production

A solar panel starts as a collection of raw materials. The main raw material in a production line is solar cells. Typically, most cells are made from silicon. The cells are wired together using a stringer. From there, glass, wiring, a backsheet, and a frame are added to make a complete solar energy module.

Once the panel is assembled it is tested for its efficiency, performance, and safety. Sorting machines then separate the modules into different categories based on their specifications.

The last step in manufacturing is of course packaging the solar cells into boxes or other containers for shipment to their destination.

How Solar Module Framing Machines Work

The frame of a solar panel equipment serves a dual purpose. Firstly, it provides structural support for the module, ensuring it can withstand high wind speeds and snowfall. Secondly, the frame serves to contain the components of a module, protecting them from the elements.

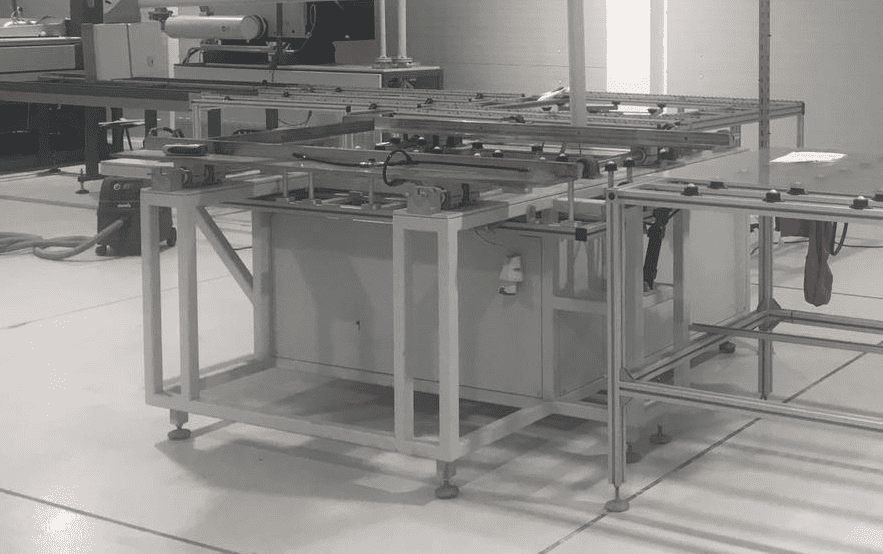

Framing machines assemble the frame of a solar PV module and place it inside the frame. The process starts with the frame assembly table, which assembles the frame of the module. The frame is then placed on the module assembly table, which places the modules into the frame.

Once the frame and modules are assembled, the frame and module clamping systems secure the frame and module in place. The frame alignment ensures the frame is properly aligned, while the module alignment ensures the modules are properly aligned.

Types Of Framing Machines

Manual: The most common framing machine is the manual machine, which is operated manually by an operator. These PV machines is typically used for small to medium-sized projects.

Semi-automated: The semi-automated machine, which is operated by an operator but with some automated features. These type of PV machines is typically used for larger production lines and is more complex to operate.

Fully automated: The fully automated machine, which is operated entirely by an automated system. This type of machine is typically used for large-scale production lines and is the most complex to operate.

Automated VS Manual PV Framing Machines

Automation technology can greatly improve the panel production process but it does make it more expensive. Just like stringers, framing machines can be automated.

Automatic solar framing machines are faster than manual machines. This reduces the amount of time required to complete the assembly process.

In addition, automatic solar framing machines are more accurate and produce panels with properly aligned frames and modules. This helps to reduce the waste generated during manufacturing, which can help to reduce costs of solar plants.

Automated PV machines are much safer to operate than manual machines, as they are equipped with a variety of safety features, such as emergency stop buttons and protective guard technologies. This helps to reduce the risk of injury to the operator.

Tips For Choosing The Right Solar Module Framing Machine

Here are the main factors to consider when choosing a framing machine.

Size of the project: If the project is small to medium-sized, then a manual machine is likely the best option. If the project is larger, then a semi-automated or fully automated machine may be better suited.

Module type: If the modules are single-cell, then a manual machine may be sufficient. If the modules are multi-cell, then a semi-automated or fully automated machine may be necessary.

Budget: Manual PV machines are typically much less expensive than semi-automated or fully automated machines, so if budget is a concern, then a manual machine may be the best option.

Packing And Sorting

PV production is a multi-stage process involving several steps and machinery. Sorting and packing are the last steps in module production.

Sorting machines are used in a variety of industries to grade the finished product. In photovoltaic module production, they are used to quickly and accurately separate solar modules into different categories based on their specifications. This helps ensure the solar modules meet the quality standards required for consumer use.

Sorting machines are typically made up of a series of conveyor belts, sensors, and robotic arms. The conveyor belts move the solar modules from one station to the next, while the sensors detect the specifications of each module.

The robotic arms then move the modules to the appropriate sorting bins. Sorting machines can be programmed to recognize the different specifications of each module and sort them accordingly.

Manual VS Automated Sorting Machines

Just like framing, sorting, and packing can be manual, semi-automated, or fully automated. Manual solar panel machines are the least expensive and are typically suited for small-scale operations. Semi and fully-automated machines are more suited to medium to large-scale solar panel manufacturing.

Automated sorting machines offer numerous benefits. The most notable benefit is the speed and accuracy with which they can sort modules. This helps manufacturers quickly identify and separate solar modules that do not meet quality standards.

Additionally, sorting machines reduce the need for manual labor. Since sorting is automated, fewer employees are required to oversee the process. This leads to cost savings for manufacturers as they do not have to hire as many employees.

Finally, sorting machines are more efficient than manual sorting. Since the process is automated, it is faster than manually sorting panels, leading to higher production rates and quicker delivery times.

Automating The Packing Process

Automation can help to ensure that the modules are packed quickly and accurately. To automate the packing process, manufacturers must first create a packing plan.

This plan should outline:

1. The number of panels that need to be packed.

2. The size and weight of the boxes.

3. The type of packing material to be used.

4. Special requirements for the packing process.

Once the packing plan has been created, manufacturers can use software to automate the packing.

Conclusion

Framing, sorting, and packing is the final step in the production of solar panels. Automation can help prevent errors and make the process more efficient.

From here, the next step is the marketing and distribution of solar panels. We have previously covered a few strategies on how to find customers for solar panels.

If you have not already, make sure to check out that article for ideas on marketing strategies you can use to grow your solar module production business.